Overview

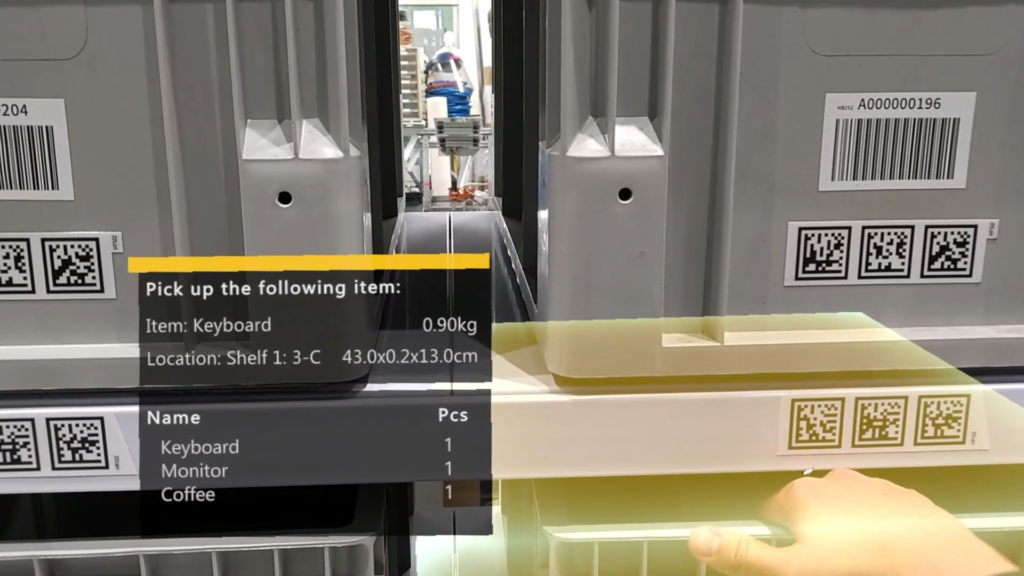

This project introduces a cutting-edge software developed specifically for the HoloLens platform, designed to revolutionize inventory management. The innovative solution leverages Mixed Reality (MR) to streamline the inventory picking process, creating an immersive experience for users. By overlaying digital information onto the physical environment, workers can easily locate and identify items in real-time, optimizing the process with greater efficiency and accuracy.

With seamless integration and advanced features, this MR-based system offers unparalleled efficiency in inventory picking, reducing human error and increasing productivity. The software provides step-by-step guidance, helping users locate items, scan them, and confirm their selections. This makes it an indispensable tool for modern warehouses and inventory management operations.

Technology and Features

- HoloLens Integration: The software is designed to work seamlessly with the Microsoft HoloLens, allowing users to interact with both virtual and physical environments simultaneously. This integration empowers workers to visualize instructions and directional cues overlaid onto their field of view, guiding them through the warehouse to pick items efficiently.

- Real-time Inventory Guidance: Workers receive real-time prompts on the items they need to pick, including details such as item names, weights, and locations (e.g., shelf numbers and specific coordinates). This ensures that workers can quickly find the correct items without confusion, reducing errors and improving overall accuracy.

- Barcode and QR Code Scanning: The system enables users to scan barcodes and QR codes directly through the mixed reality interface, ensuring that the correct items are picked and logged in the system. This feature minimizes the need for manual checks and data entry, further streamlining the workflow.

- Visual Path Navigation: The software provides visual navigation cues in the form of arrows and highlights, directing pickers to the exact location of each item. This feature eliminates guesswork and reduces the time spent searching for items, making inventory picking more efficient.

Key Benefits

- Enhanced Efficiency: The Mixed Reality interface significantly improves the speed and accuracy of the inventory picking process by providing real-time guidance and reducing human error.

- Streamlined Workflow: With features such as barcode scanning and visual path navigation, the system ensures that workers can quickly locate, scan, and confirm items, streamlining the entire inventory process.

- Improved Accuracy: The combination of real-time data, augmented instructions, and automatic item verification reduces the likelihood of picking errors, leading to more reliable inventory management.

- User-friendly Interface: The HoloLens platform enables a hands-free and intuitive interface, making it easy for workers to follow instructions and complete tasks without needing to handle additional devices or paperwork.

Watch a Demo

This project demonstrates the power of Mixed Reality in optimizing inventory operations, enhancing both efficiency and accuracy. By utilizing HoloLens technology, it offers a next-generation solution for warehouses and inventory management.